Bentonita is used in large quantities across many industrial sectors, including steel mill smelting pellet production, casting, non-excavation works, oil drilling, petrochemicals, pharmaceuticals, pesticides, and agricultural fertilizers. Bentonite specifications generally refer to its packaging requirements, which vary by industry. Here is an overview of bentonite specifications for different applications:

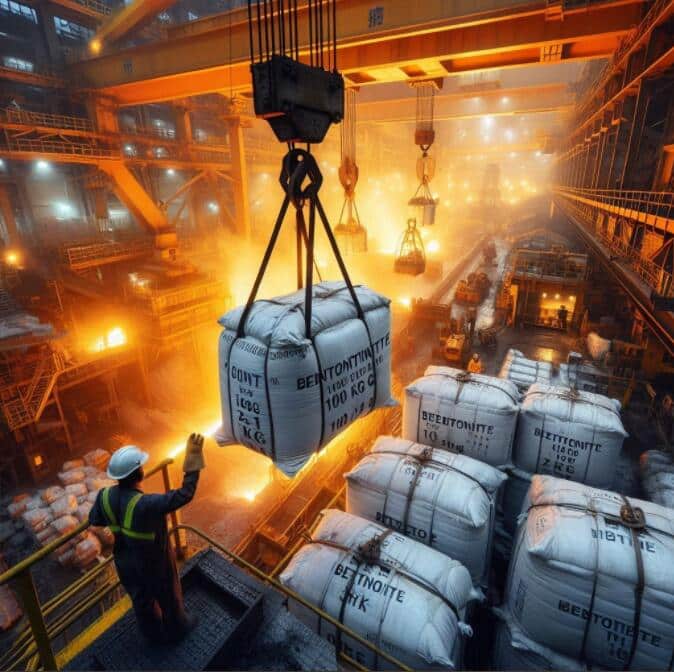

- Steel Mill Smelting Pellet Production: Bentonite is typically fed into metallurgical processes using aerial cranes. Therefore, packaging specifications are generally 1,000 kilograms per package, commonly known as ton packages. Half-ton packages (500 kilograms) are also used.

- Non-Excavation Construction: In these projects, bentonite is used to thicken slurry. Slurry pools are usually 4×4 meters, with 150-200 kilograms of bentonite added at a time. This is a manual process, so the preferred packaging is 25 kilograms per bag for easy handling.

- Pharmaceutical Industry: The purity and taste requirements for bentonite are very high in this sector. Pharmaceutical production lines are delicate, making it impractical to handle large raw material packages. Therefore, bentonite is typically packaged in 2-10 kilogram bags for this industry.

In summary, bentonite packaging specifications depend on the industry and site requirements. Common packaging sizes include 2 kg, 5 kg, 10 kg, 25 kg, 40 kg, 500 kg, and 1,000 kg.

Understanding these specifications, San Ding Technology Co., Ltd., founded in 2002, specializes in the development, production, and sales of montmorillonite products. In 2013, the company registered Hubei Sanding Technology Co. In 2016, they built China’s first fully automatic montmorillonite deep processing production line. The company has passed ISO9001 international quality system certification and has a municipal R&D center, two non-metallic deposits, two modern factories, and four montmorillonite deep processing production lines. It also serves as a production, learning, and research base for the Ministry of Education’s Engineering Research Center for nano-mineral materials and applications.

The company’s R&D strength is significant, with a team of 19 people, including prominent external experts such as Prof. Zhang Lide, chief nano-scientist of the Chinese Academy of Sciences; Prof. Yan Chunjie of China University of Geosciences (Wuhan); Dr. Yang Zhihong of China University of Geosciences (Wuhan); and Dr. Zuo Shufeng of Shaoxing College of Arts and Sciences. Since its establishment, Tecnología de lijado has undertaken 11 provincial and municipal scientific research projects and over 10 lateral projects, investing more than 26 million yuan in R&D and over 100 million yuan in the montmorillonite industry. The company has declared 3 new products at the provincial level, applied for 12 invention patents and 1 utility model, and received 7 patent certificates. With over 30 core technologies and more than 70 published articles on montmorillonite applications, Sanding Technology continues to lead in innovation and development in this field.