Your Reliable Bentonite Manufacturer and Supplier

- 20+ Years of Experience in Production of Bentonite Clay

- 30+ Core Technologies for Bentonite Manufacturing

- Trusted by 50+ Clients All Over the World

Most Popular Products of Sanding Bentonite

Get what you need even the customized bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Bentonite

Who is Sanding Bentonite?

Do you often need help finding suitable bentonite clay suppliers? Do you want a bentonite clay product that can meet your requirements? Do you want a bentonite clay solution that can save you time and cost?

If you answer yes, you have come to the right place. We are Sanding Technology Co., Ltd, a national critical high-tech enterprise specialising in the research, development, production and sales of bentonite clay products. We can offer you the following advantages:

High product quality through the ISO9001 international quality system certification, in line with international standards. Our products are subject to strict quality inspection and testing to ensure their performance and safety. Our products improve your productivity and profit and protect your health and environment. Whether in medicine, animal husbandry, daily chemicals, industry and so on, our products can play an excellent role so that you can quickly meet various challenges.

We have a wide range of products, covering four series:

- The Dinetteette series for pharmaceuticals

- The UYNULE series for animal husbandry

- The Yogum series for daily chemicals

- The Senjiu series for industry

These products result from our research development and innovation, featuring high efficiency, safety, environmental protection and stability. They can meet the needs and expectations of different customers. Whether you need to improve soil structure, increase crop yield, improve feed quality, purify water, prevent diseases, beauty care, paint fillers, etc., we can provide you with the right products and suggestions.

Why Choose Sanding Bentonite Clay

Your Best Bentonite Clay Manufacturer and Supplier in China

20+ Years of Bentonite Manufacturing Experience

Sanding Bentonite has 20+ years of bentonite manufacturing experience. As a professional bentonite clay supplier and manufacturer, we have been committed to providing high-quality bentonite clay products and services since our establishment in 2002. Our bentonite clay is widely used in industry, agriculture, environmental protection, medicine, chemical, beauty and other industries.

Professional After-Sales Service and Technical Support

Sanding Bentonite Clay is committed to providing high-quality after-sales and technical services. We will carefully solicit feedback and suggestions from each customer. If you have any questions or are dissatisfied with our bentonite clay products and services, you can contact our customer service team at any time, and Sanding Bentonite Clay will take care of the problem for you as soon as possible. We also provide free technical support and guidance to help you better use and understand our bentonite products.

Free Samples are avaiable

Sanding Bentonite Clay also provide free bentonite sample service, allowing you to test bentonite samples before placing an order to ensure that you purchase the bentonite that meets your needs.

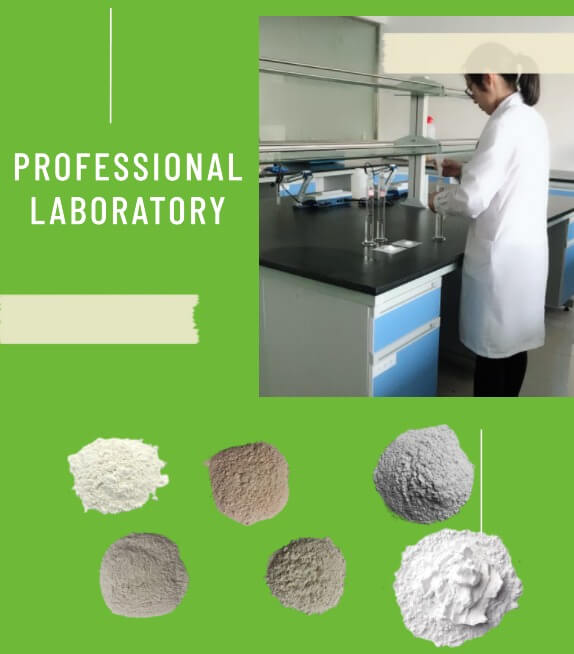

Advanced Production Equipment and Technology

Sanding Bentonite Clay has advanced production equipment and technology. Our company covers an area of more than 100,000 square metres. It is equipped with several automatic assembly lines and testing equipment to ensure that bentonite products meet national standards and customer requirements every time. Sanding Bentonite Clay R&D team continues to explore and innovate to improve technology and develop more bentonite products that blend into different uses and needs.

Stable and Competitive Logistics Services

Sanding Bentonite Clay is committed to providing fast logistics and distribution services and cooperating with several internationally renowned airlines and maritime logistics companies to ensure a stable and competitive logistics service. This cooperation ensures that your bentonite purchase order can be safely delivered to the specified destination within a short period.

Trusted by 50+ Worldwoide Clients

Sanding Bentonite Clay trusted by our customers are located worldwide, including Europe, North America, Asia, Africa and Oceania.

Customer-centric Service:

Sanding Bentonite Clay offer you competitive prices and flexible payment options. As a vertically integrated bentonite clay manufacturer and supplier, Sanding Bentonite Clay directly process the bentonite from raw material extraction to finished product, helping you to prevent the cost of middlemen and offer the most competitive price. In addition, Sanding Bentonite Clay offer various international trade payment options that can be selected based on your practicality and convenience as a bentonite distributor.

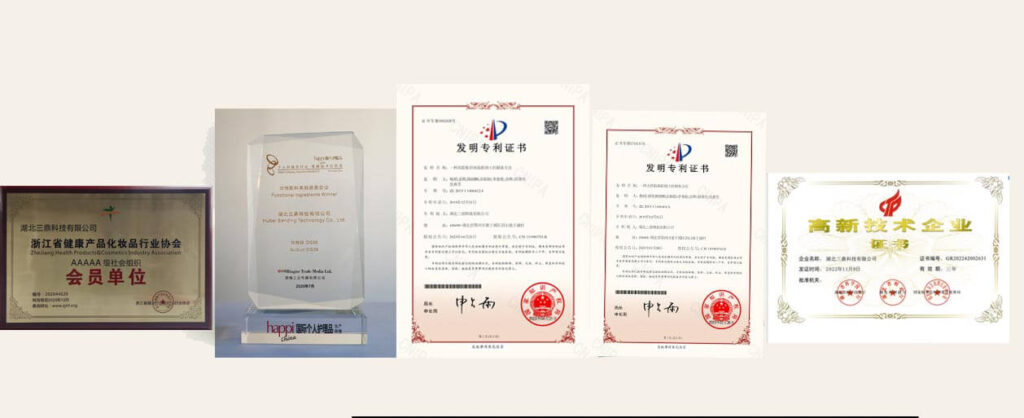

Have a Good Reputation from Clients

Sanding Bentonite Clay enjoy a good reputation and credibility. As an ISO9001-compliant company, Sanding Bentonite Clay is a bentonite supplier and manufacturer. Our products have passed SGS, CE and other international certificates to gain recognition in the global market, and in international trade, we are trusted and recognised by international bentonite buyers. Sanding Bentonite Clay's customers highly appraise and recommend our bentonite products and services.

Reliable Supply Chain and Stable Supply Capacity

Sanding Bentonite Clay has established a stable and reliable supply chain system to ensure timely delivery and solve the problem of unstable supply in your procurement process.

Bentonite Clay Manufacturing Process

Bentonite is a kind of water-containing silicate-aluminium mineral with montmorillonite as the main component, with the advantages of absorption, presentation, thixotropy, thickening, etc. It is widely used in oil and grease, coatings, textiles, daily chemical industry, environmental protection, etc. The critical steps of bentonite processing are as follows:

Beneficiation: mining bentonite ore from natural coal mines to remove stones, weeds and other impurities by artificial or mechanical means to enhance the purity and taste of the original ore. After beneficiation, the raw ore is inspected, checking its montmorillonite composition, heavy metal content, harmful substances and other data, and classified and stored according to different grades.

Sodiation: Sodiation converts calcium- or magnesium-based bentonite into sodium-based bentonite, aiming to enhance bentonite’s water absorption and expansion multiplier to improve permeability and gel price. Many sodium modification methods exist, such as standard mixing, yard, extrusion, etc. Sodium modifier is generally sodium carbonate or bicarbonate; sodium silicate or other organic matter can also be used. Sodium bentonite, after maturation, is placed at a specific temperature and humidity for some time, sufficient to absorb nutrients and interchange ions to achieve the desired characteristics.

Drying: Drying removes moisture from senescent bentonite, aiming to reduce the water content, convenient for the next step of crushing and packaging. There are many drying methods, such as a rotary kiln, spray dryer, fluidised bed, etc. The dried bentonite should be controlled within the 20-30% moisture content range.

Grinding: Grinding is adjusting the particle size of dry bentonite, aiming to achieve different uses and customer needs. There are many varieties of mills, such as Raymond mill, airflow mill, ball mill and so on. After grinding, the bentonite should do a particle size test and test its percentage through a variety of mesh sieves, such as 80 mesh, 200 mesh, 325 mesh, etc… After the particle size test is qualified, it should also be a comprehensive test to detect its water absorption, expansion times, gel price, pH value and other indicators.

Packaging: packaging is the process of bottling and packaging qualified bentonite to facilitate transport and storage. There are many packaging methods: everyday bags (liner bags), paper bags, tonne bags, etc. Packaged bentonite should be marked and recorded with its name, specifications, batch number, production date and other information and sent to the finished product warehouse storage.

Accept Customized Bentonite Clay Order

Product customisation, according to your specific needs, we can provide you with exclusive bentonite clay solutions. Whether you need to adjust the particle size, purity, activity, colour and other parameters of the product or need to develop new functional or composite bentonite clay products, we can provide you with professional technical support and services. We can meet your needs, foresee your future needs and provide continuous innovation and improvement.

Certificate and Exhibition of Sanding

As a professional bentonite clay products supplier, we not only provide you with high-quality products but also provide you with high-quality service. We have always pursued the business philosophy of “specialising and strengthening, seeking refinement and innovation, and building a win-win situation”, and with the product tenet of “safety, greenness, professionalism and quality”, we have built an internationally famous brand of bentonite clay with the ability of customised service for the whole industrial chain.

What Our Clients Say About Us

Blog and News from Sanding Bentonite

The Rising Popularity of Bentonite in Skincare Products: Applications and Benefits

The desire for natural skin care ingredients is growing. Bentonite, a versatile natural clay mineral, has become popular in skin care products. It has unique

Beneficial Applications of Bentonite in Personal Care: A Comprehensive Guide for International Buyers

The Use of Bentonite in Personal Care Products Bentonite is widely utilized in personal care products with its various excellent properties. 1. Bentonite clay Use

Bentonite in Personal Care: Benefits, Applications, and Future in Cosmetics

Bentonite is a natural mineral with superior adsorptive, moisturizing, and thixotropic properties and is widely used in personal care and household chemicals. As a cost-effective,

Bentonite Development and Utilization of the Current Situation and Countermeasures Proposed

In the full collection of research data on the basis of the elaboration of China’s bentonite resource characteristics, analyse the development and utilization of the

How to Use Bentonite Clay in the Best Way? Learn More About Bentonite Clay Tips for Foundry

The Role and Changes of Bentonite in Clay Bonding Sand The bentonite used in casting mainly includes sodium bentonite and calcium sodium bentonite. Sodium bentonite

Top 11 Bentonite Manufacturers Worldwide

Bentonite, an adaptable clay material, finds wide application across industries. Thanks to its properties – water absorption and expansion – bentonite has found widespread usage