Although the production of China’s bentonite industry has declined, the market demand is still growing steadily

Bentonite industry is the industrial field in which bentonite is the primary raw material. Bentonite is a natural mineral with excellent physicochemical properties and is widely used in various industries, such as construction materials, environmental engineering, metallurgy, and ceramics. Bentonite industry, through the mining, processing, and utilization of bentonite resources, produces and sells various bentonite products for other industries to provide critical raw materials and technical support. The development of the bentonite industry is essential to promote economic growth, enhance industrial competitiveness, and promote sustainable development.

Bentonite is a non-metallic mineral; the main component is montmorillonite. Montmorillonite’s crystal structure is bentonite’s core feature, consisting of two silica-oxygen tetrahedra sandwiched between a layer of aluminum-oxygen octahedra to form a 2:1-type structure. Montmorillonite crystal cells are layered and contain cations such as Cu, Mg, Na, K, etc. These cations are unstable in their interactions with the montmorillonite cells and are easily replaced by other cations, so bentonite has good ion exchange properties. Bentonite is also known by other names, such as porphyritic, soapstone, or bentonite. In China, bentonite has a long history of development and utilization. Initially, it was only used as a detergent. However, bentonite has been widely used in various fields in the last hundred years.

Bentonite is widely used in many fields and can be classified according to its applications

A standard industry classification of bentonite is based on its use.

First is the construction industry; bentonite can be used to improve and enhance concrete, mortar, coatings, and other building materials.

Second is the oilfield industry; bentonite can be used in oil well drilling, cementing, and related processes in oilfield development.

In addition, bentonite can be used in soil improvement, environmental protection, ceramics, and glass industries.

In addition to being classified according to its use, bentonite supplier can also be categorized by industry based on its production.

For example, one industry that mainly produces bentonite is the mining industry, where these bentonites are obtained primarily using mining and extraction.

Another industry is the chemical industry, and these bentonites are obtained through chemical reactions and processing.

In short, there are many ways to categorize the bentonite industry, mainly based on its application areas and production methods.

Depending on the type and content of exchangeable cations between the different montmorillonite layers, bentonite can be divided into four main types: calcium-based bentonite, which contains a high proportion of calcium ions; sodium-based bentonite, which is characterized by a high content of sodium ions; magnesium-based bentonite, whose main constituent is the magnesium ions; and aluminum (hydrogen) bentonite, where aluminum ions or hydrogen ions occupy a prominent position.

Calcium-based bentonites are montmorillonite and illite and are more commonly found in marine sediments and volcanic ash. Despite its weak adsorption capacity, calcium-based bentonite has good stability and resistance to high temperatures. Sodium-based bentonite is composed primarily of montmorillonite and other bentonite minerals and is found primarily in river and lake sediments. In addition, there is also a kind of illite bentonite, a mineral with a more complete layered structure, mainly composed of silicates and hydrated aluminum silicates. Ilmenite bentonite is highly absorbent and is capable of adsorbing and retaining large amounts of water.

The development experience of the bentonite industry

With the continuous progress of science and technology and in-depth study of bentonite properties from the 1970s to the 1980s, the scope of application of bentonite was gradually expanded to cover a variety of fields such as environmental protection, agriculture, and food processing. At the same time, bentonite mining and processing technology has also been significantly improved.

Into the 1990s, due to globalization, the bentonite market is increasingly international. China and other resource-rich countries began to increase investment in the bentonite industry and development efforts, making large-scale production and export mainstream.

The bentonite industry entered a rapid development stage in the 21st century, especially between 2000 and 2010. Technological innovation has driven the increase in product variety, including developing and applying high-performance materials such as organic bentonite. These new materials have found a broad market in oil exploration, coatings, cosmetics, and other fields.

Since 2010, the bentonite industry has been deepening structural adjustment and industrial upgrading, emphasizing green and sustainable development. China and other major producing countries have implemented strict environmental policies and industry norms, promoting the industry’s transition to high efficiency, environmental protection, and high-end direction. Meanwhile, increasing investment in scientific research and the commencement and expansion of new projects such as the 30,000-ton annual bentonite production line in Qufu, Shandong Province (2020) and the new bentonite material project in Ningguo City, Anhui Province (2020) has further consolidated and enhanced China’s position in the global bentonite industry chain.

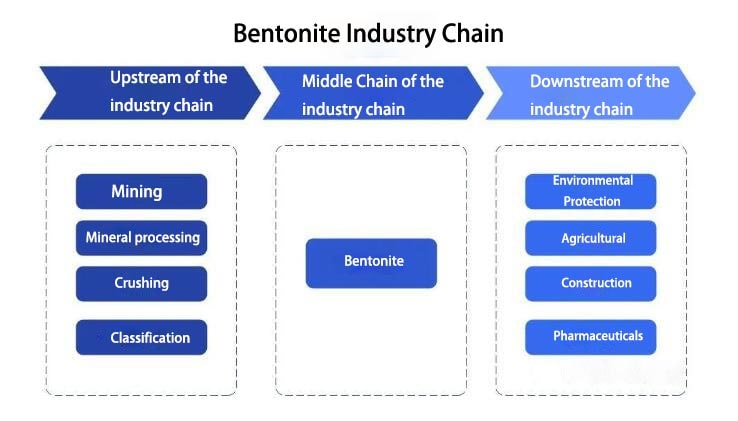

The bentonite industry covers the supply chain’s upstream, midstream, and downstream.

The upstream of bentonite mainly refers to the mining and processing of bentonite ore, including mining, beneficiation, crushing, grading, and other links. Bentonite ore is primarily found in river and lake sediments, marine sediments, and volcanic ash, so it is widely distributed, but there are relatively few high-quality ore resources. Bentonite’s downstream application fields are vast, mainly including environmental protection, agriculture, construction, medicine, etc. In environmental protection, bentonite can be used in water treatment, exhaust gas treatment, and solid waste treatment. In agriculture, bentonite can be used as soil conditioners, pesticides, and feed additives. In construction, bentonite can be used to produce building materials, waterproof materials, and thermal insulation materials. In medicine, bentonite can prepare drug carriers, drug release systems, and dressings.

Market volume and growth rate of China’s bentonite industry

China is a large country with vast reserves of bentonite resources globally. According to statistics from the Ministry of Natural Resources, China’s bentonite reserves have reached 332,718,500 tons as of 2022, an increase of 32 million tons from the previous year. This mineral resource is widely distributed in China, covering 23 provinces and regions, with significant production mines located in Xuanhua, Hebei, Yuhang, Zhejiang, and Longhua, Hebei. Concerning domestic consumption, bentonite products are widely used in several industries. Among them, the metallurgical industry of iron ore pellets required the most significant demand for bentonite, accounting for about 51% of the total consumption; in the foundry industry, the proportion of consumption is about 15%; and in the field of drilling mud consumption ratio occupies about 18%. In addition, bentonite is widely used in the petrochemical, light, textile, agriculture, and building industries.

According to statistics, during the five years from 2016 to 2020, the annual production of bentonite in China remained between 3.2 million tons and 3.65 million tons. During this period, the demand for bentonite in traditional industries such as foundry sand, drilling mud, and metallurgical pellets accounted for approximately 85% of the total average annual production. China’s bentonite market size reached about RMB 6,598 million by 2022, representing a growth of 44.9% compared to the previous year, indicating strong market dynamics. However, due to the stabilization of demand in the downstream industry and the increasingly stringent standards, the output of bentonite in China has declined significantly. In 2022, China’s bentonite output was approximately 2.1 million tons, the same as the previous year. At the same time, market demand showed a moderate growth trend. In the same year, China’s demand for bentonite was 1.9704 million tons, an increase of 5% over the previous year, indicating that market demand is still growing steadily despite the decline in production.

In 2022, China’s bentonite market will be approximately RMB 6.598 billion, an increase of 44.9% from last year. However, it is essential to note that during the same period, there was a significant decline in bentonite production, which stabilized at 2.1 million tons for the year, unchanged from the previous year. Despite the decrease in production, market demand is still growing, reaching 1.9704 million tons in 2022, up 5% year-on-year. From the enterprise level, take Hongyu Shares as an example; this is a high-tech enterprise founded in 2010 focusing on the research, development, production, and sales of organic bentonite.

The company has a mature organic nano-bentonite production line. It occupies a place in the market with its main product, HY series organic bentonite.2022, the bentonite business of Hongyu shares achieved an operating income of 158 million yuan, an increase of 22.39% year-on-year, and maintains a high gross profit margin of 30.82%. China has rich and diverse bentonite mineral resources, including calcium-based bentonite, sodium-based bentonite, hydrogen-based bentonite, aluminum-based bentonite, sodium-calcium-based bentonite, and others. Calcium-based bentonite is the most abundant, accounting for more than 80%. As of 2019, China has 223 proven bentonite mining areas, with a cumulative identified resource reserve of up to 3.005 billion tons.

China’s bentonite exports are mainly concentrated in Southeast Asia, including Indonesia, Thailand, Malaysia, and South Korea. Specifically, in 2021, the highest export volume to Indonesia reached 67,000 tons, accounting for 17% of China’s total bentonite exports. This is followed by Thailand and Malaysia, with exports of 58,900 tons and 53,300 tons, accounting for 15% and 13.5%, respectively.

Bentonite industry policies

The bentonite industry’s policies mainly cover environmental protection, safety, and quality regulations. In terms of environmental protection, the government has set strict restrictions and regulatory measures on the mining, processing, and utilization of bentonite to ensure the environment’s and ecosystem’s stability. In terms of safety, bentonite enterprises are required to establish a comprehensive safety production management system and strengthen equipment maintenance and personnel training to ensure the safety of the production process. Regarding quality, the government has formulated a series of standards and norms to require bentonite products to meet the relevant quality requirements and strengthen the supervision and inspection of product quality. In addition, the government also encourages and supports technological innovation and development of the bentonite industry to enhance the competitiveness of enterprises and market share.

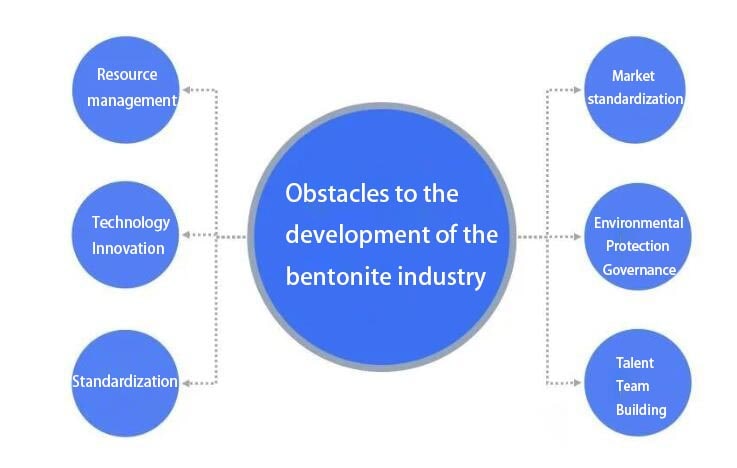

Challenges faced by the bentonite industry

Regarding resource management, there are problems of excessive extraction and irrational utilization in the industry, which wastes valuable bentonite resources and triggers environmental damage and ecological imbalance. Secondly, the gap in the level of technology and equipment is an obvious problem. Some small enterprises need to be more forward in production equipment and technology, resulting in unstable product quality, inability to meet high-end market demand, and increasing environmental impact.

The need for more research and development and innovation capacity has become a critical bottleneck in the industry. Presently, bentonite products are mainly concentrated in the low-end market, and the supply of high-end products needs to be increased, limiting the industry’s development space and competitiveness. In addition, the imperfect construction of the standardization system is also a factor restricting the sector’s development. Product standards and testing methods are unique and non-standardized problems affecting market competition, consumer rights, and interest protection. In terms of market order, due to the low degree of industry concentration, market competition is chaotic, with frequent price wars, seriously affecting the industry’s profit level and healthy development.

Environmental issues in the bentonite industry must face a severe challenge: the need to effectively solve the production process of wastewater, waste gas, and waste residue treatment to achieve a harmonious coexistence with the environment. Talent team building is also a short board that can not be ignored. Shortage of professional and technical personnel and senior management personnel, limiting the ability of enterprises to enhance technological innovation and business management, thereby restricting the long-term development and transformation and upgrading of the industry as a whole.

Predict the future development prospects of the bentonite industry.

With the progress of science and technology and the continuous diversification of market demand, the application of bentonite is also expanding. In addition to the traditional casting, drilling, chemical industry, agriculture, and other fields, bentonite is now beginning to play a role in environmental protection, new materials, new energy, and other high-tech areas. This change has brought fresh impetus to the development of bentonite. In the future, it is expected that this industry will enhance bentonite technological research and development and innovation capabilities, strengthen basic research and deep processing technology innovation, and promote the development of processing equipment in a large-scale, intelligent direction to improve product quality and resource utilization efficiency. This will help develop a series of high-end bentonite products that meet the needs of different markets and make full use of the resource advantages of China’s bentonite mines.

With the global demand for energy-saving and environmentally friendly functional mineral materials growth, bentonite is an essential practical mineral material, and its export market is expected to expand further. At the same time, the standardization of the industry will be strengthened, which is conducive to enhancing the international competitiveness of China’s bentonite products. In general, the bentonite industry is expected to achieve sustained and stable development through technological innovation, industrial restructuring, and environmental upgrading and constantly improve the industry’s value and global influence to contribute to the sustainable development of the economy and society.